Reimagining modern mining engineering with Dyneema® DM20 fiber

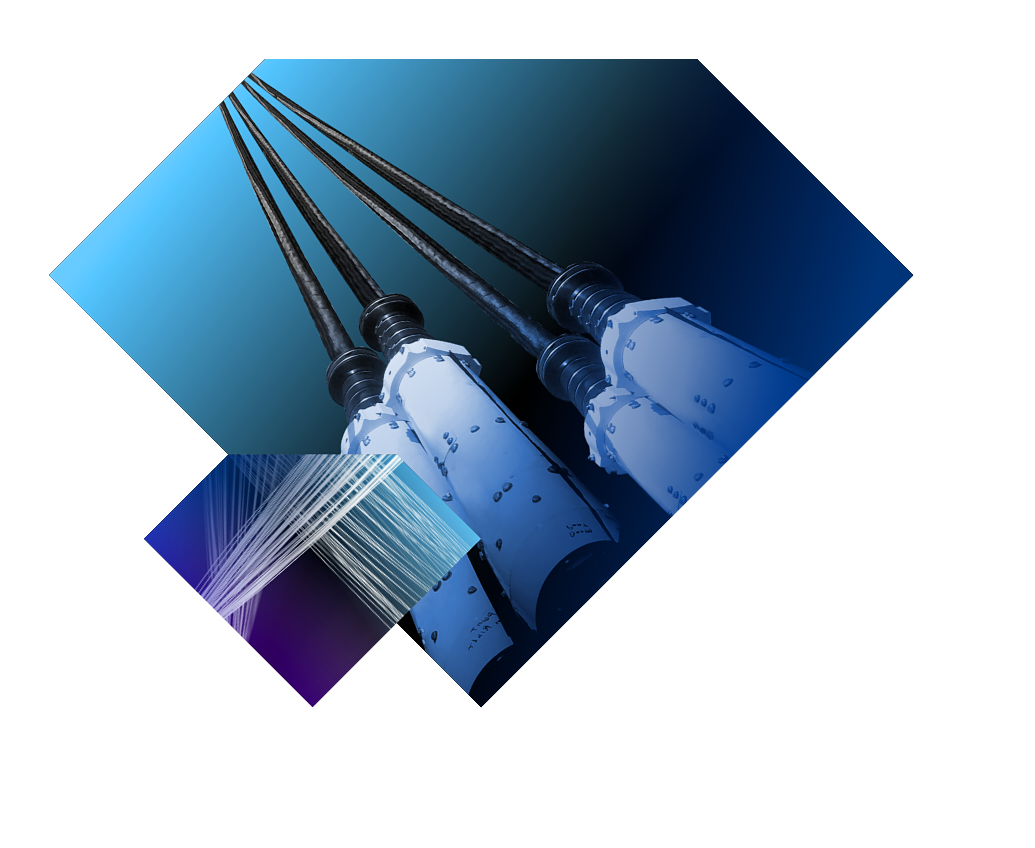

In 2016, we became part of a (literally) groundbreaking project at a Wyoming mine: installing the world’s first-ever fiber dragline mining pendants. Produced by our partner Applied Fiber, these main-boom pendants were made with Dyneema® DM20 fiber – a superior solution to steel wire ropes in this critical mining application.

More than eight years later, our custom-engineered low-fatigue grade of fiber has far exceeded expectations. With the Dyneema®-based ropes having surpassed the lifetime of steel alternatives, our fiber has proven itself a global game-changer, capable of helping the mining industry dig into a rich seam of valuable benefits.

Dyneema® DM20 fiber enables safer and more cost-effective mining

MADE FOR: Mining draglines

Mining shovel pendants

Dyneema® enables STRENGTHplus+

Dragline and shovel pendants made with Dyneema® are uniquely strong – and Dyneema®-based pendants are in it for the long haul. In fact, the seven-year inspection in Wyoming found that the ropes not only were still performing at a high level, but also still appeared nearly new.

Reliably reduced vibrations

Operators might enjoy a great view from the cabin – but they don’t enjoy eight hours of intense vibrations from steel wire pendants. Every shift can have a negative physical impact on the body, as well as causing mental stress.

The good news? Switching to a synthetic boom can make all the difference. Dragline main-boom pendants made with Dyneema® DM20 fiber dramatically reduce the vibrations that are transferred to the cabin – for lower shock force, fewer injuries, and a more pleasant operating experience.

For reliable comfort

Greater comfort and safety for operators

Significant shock force reduction

Greater comfort and safety for operators

Hitting new heights of operational efficiency for the mining industry

Dyneema®’s unique strength-to-weight ratio is a critical advantage in dragline applications: after all, heavy steel pendants put strain on people and machinery alike in an already-tough mining environment. Thanks to synthetic main-boom pendants made with Dyneema® DM20 fiber, mining operators enjoy a dramatic weight reduction that, in turn, increases the crane’s payload capacity.

What’s more, lightweight ropes are easier for crews to work with, making handling safer and faster. And they reduce the risk of boom fatigue and cracking, protecting valuable equipment and saving time on maintenance. In short, less weight means more operational efficiency – and in mining, every cycle counts.

For greater efficiency, day after day

Huge weight reduction versus steel

Lightweight ropes mean increased payload capacity

Reduced boom fatigue and cracking

Lower installation, maintenance, and replacement costs

Easier, safer, faster handling

Unmatched dragline durability with no end in sight

The downtime needed to maintain or replace steel wire ropes is a headache for the mining industry. But dragline and shovel pendants made with Dyneema® DM20 fiber can ease the pain and boost mines’ performance and cost efficiency.

How? Because, after seven years of operation, the Dyneema®-based ropes have hit a major milestone, exceeding the lifetime of traditional steel alternatives and continuing to perform reliably at a high level. They still look nearly new. They need less maintenance and less frequent replacement. And they’re so easy to install that, when they do need to be replaced, it takes just a fraction of the time.

For greater durability than steel

Still performing strongly and looking nearly new after seven years

311 million low-range and 5.8 million peak-load cycles – and counting

Less maintenance downtime

Faster replacement processes

Lower cost of operations, maintenance, and installation

Draglines and shovel pendants that are more sustainable

Sustainability is a hot topic in the world of mining – meaning that every rope, dragline, and pendant bears the weight of intense scrutiny. Thanks to Dyneema® fiber, manufactured from 100% renewable electricity, mine operators can reduce their carbon footprint with no risk of adverse effects on performance.

And that’s not all: Dyneema®’s low weight enables less energy use in transport and operations, and rope shovels and dragline pendants made with our fiber have a superior service life, delivering greater resource efficiency.

Want even more sustainable operations? Certified by the International Sustainability and Carbon Certification (ISCC), Dyneema® fiber from bio-circular feedstock is the world’s first bio-circular HMPE fiber – delivering top-quality performance with a reduced environmental impact.

For a big impact with a small footprint

Reliably longer service life enables less resource consumption

Low weight means less energy use

Dyneema® fiber from bio-circular feedstock available

Want the same high performance with a lower carbon footprint?

Discover Dyneema® fiber from sustainable raw materialsContact our sales team

Ready to embrace the future of mining and improve the safety, efficiency, and sustainability of your operations? We don’t blame you! Our experts are on hand to answer your questions and support you in replacing your steel draglines and shovel pendants with next-generation solutions made with Dyneema®.

Contact usDyneema®: Delivering unparalleled performance

A groundbreaking milestone for the world’s largest earth-moving machines: discover how dragline pendants made with Dyneema® DM20 fiber have revolutionized mining engineering for Cloud Peak Energy.

Dragline and shovel pendant supplier and partners

At Dyneema®, we work hand in hand with premium partners to manufacture only the highest-quality products using our fibers. Together with Applied Fiber, we co-developed these high-performance dragline pendants to protect against boom fatigue while increasing payload capacity – and the resulting next-generation ropes more than deliver on their promise.

Where to buy

Dragline and shovel ropes made with Dyneema® fiber are available across the globe from our trusted partner.

Find a providerExplore more

Offshore crane ropes and winchlines

Deep-water crews need ropes they can rely on – and Dyneema® is the clear choice for safe and efficient lifting.

Engineered lifting slings

Dyneema® SK78 fiber makes light work of heavy lifting as a key ingredient in strong, reliable, and sustainable slings.