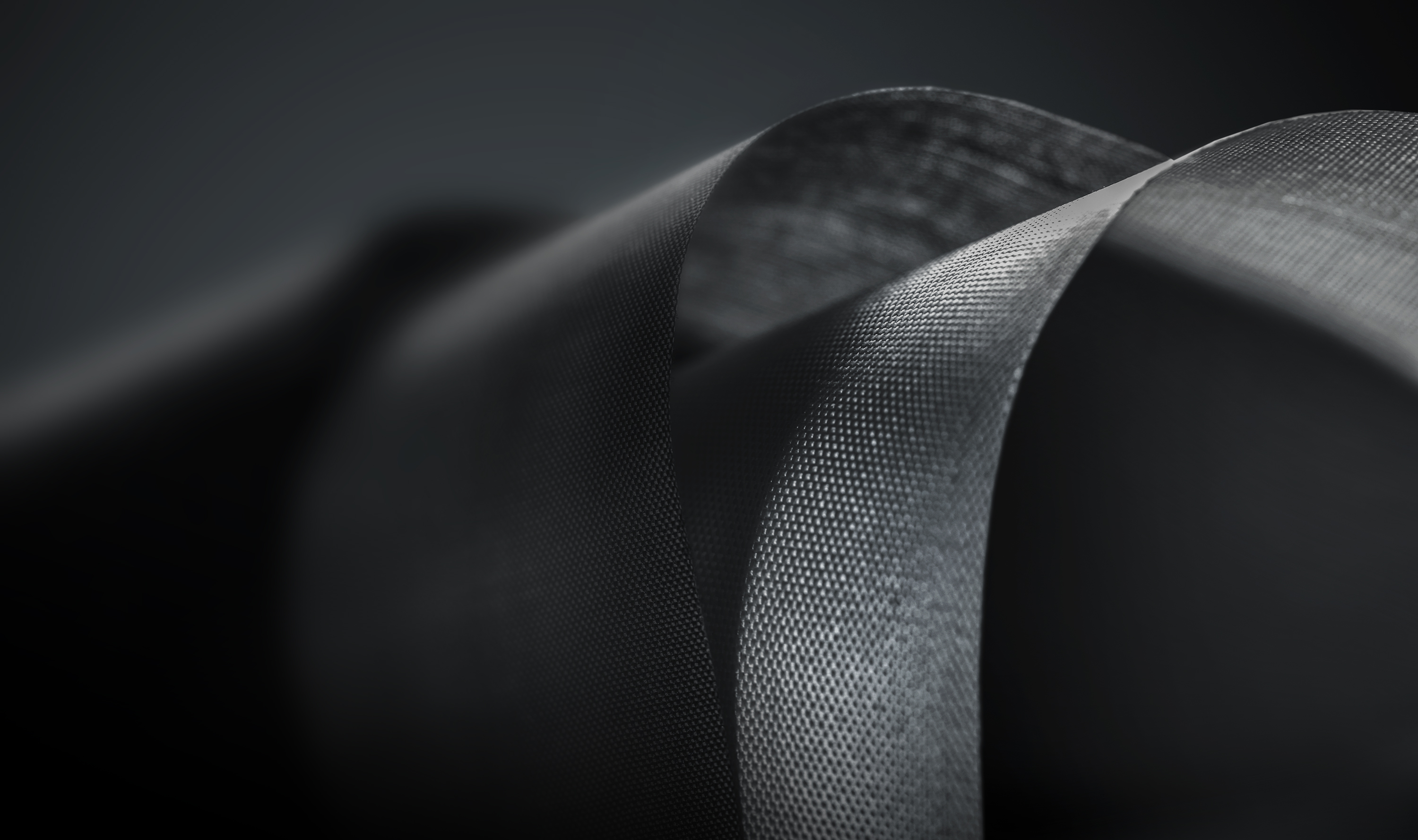

Breaking new ground with our latest innovation

For over a decade, Dyneema® has been the material of choice inside the world’s best-performing outdoor gear. Built to conquer the harshest terrains on the planet, our composites help elite mountaineers and backcountry thrill-seekers explore further and climb higher.

Now, we’ve raised the bar yet again. Meet Dyneema® Woven Composites.

Our latest innovation pushes performance to new heights. After two years of relentless R&D, we’ve meticulously crafted a composite that doubles down on the core durability, abrasion resistance, and dimensional stability of Dyneema®. A composite that delivers extraordinary strength – inside and out.

The anatomy of Dyneema® Woven Composites

To create Dyneema® Woven Composites, we begin with our trademark Dyneema® core, created by layering and bonding Dyneema® fibers at 0° and 90° orientation. This cross-ply structure prevents the individual fibers from shifting and ensures long-lasting shape retention.

Next, we use more Dyneema® fibers to craft an ultra-lightweight woven face fabric, which is bonded to the original Dyneema® core. This exterior face layer – made entirely from Dyneema® fiber – unlocks unprecedented levels of abrasion resistance and brings the unrivaled strength-to-weight ratio of Dyneema® right to the material’s surface.

Double the Dyneema®

Innovation is in our DNA. And in our latest composite, we’re doing something we’ve never done before.

We’re using the world’s strongest fiber™ on both the internal and external layers of Dyneema® Woven Composites – and literally doubling the Dyneema®.

Eliminating crimp for better structural stability

In composite construction, “crimp” refers to how much individual fibers within a yarn bend when woven over and under each other. Conventional woven fabrics have thousands of interlacing yarns, which can stretch and sag under heavy loads due to high crimp.

Dyneema® Woven Composites eliminate this issue. Their rock-solid Dyneema® core is bonded to a 100% woven Dyneema® face fabric, which locks the woven face layer in place. This results in almost zero crimp, ensuring lasting shape and durability.

Performance benefits at a glance

Dyneema® Woven Composites are engineered with multiple built-in technical advantages, including:

Discover the full Dyneema® composites portfolio in our Fabric Finder.

Learn moreProven performance through rigorous testing

Every Dyneema® composite undergoes extensive laboratory testing to ensure it meets the highest standards for strength, durability, and performance.

Our in-house laboratories conduct:

Tensile testing

Tear testing

Puncture testing

Peel strength testing

Taber abrasion testing

Hydrostatic head testing

Precision microscopy

Tried and tested out in the wild

At Dyneema®, we know a lab-ready solution still needs to prove itself out in the real world. And who better to sample a material designed for extreme sports than top-level athletes?

That’s where our partner, Hyperlite Mountain Gear, came into play. With the help of their large network of athletes and mountaineers, we tested prototype backpacks during months-long expeditions on the most extreme trails imaginable.

Finally, we used all the results and feedback to put the finishing touches to our next-generation innovation.

Where precision meets performance: our most durable composite to date.

Discover all the details about Dyneema® Woven Composites.Dyneema® in the spotlight

A breakthrough like Dyneema® Woven Composites doesn’t stay under the radar for long. Our latest innovation is turning heads – and for good reason. Check out the latest coverage from leading industry outlets.

Wonder how Dyneema® Woven Composites enhance Hyperlite Mountain Gear’s latest backpack range?

For the full story, download our digital brochure.

Explore more

Protective apparel

Extreme sports require extreme protection. Higher concentrations of Dyneema® produce gear for high-stakes applications.

Tents, packs & Bags

Hikers want reliable, durable, lightweight gear, whatever the weather – and Dyneema® lightens the load of adventure.

Outdoor gear

In changing conditions, Dyneema® never lets adventurers down, enabling strong, lightweight, waterproof, and durable gear.