Enjoy a good haul for the long haul with Dyneema® fiber

Today’s aquaculture farmers are facing the challenge of putting fish on people’s plates more sustainably. And for that, they need reliable equipment that delivers long-lasting results in all conditions. The high-strength of Dyneema® fiber helps ensure that vital fish farming equipment performs better for longer.

Dyneema® enables superior, reliable solutions for aquaculture applications

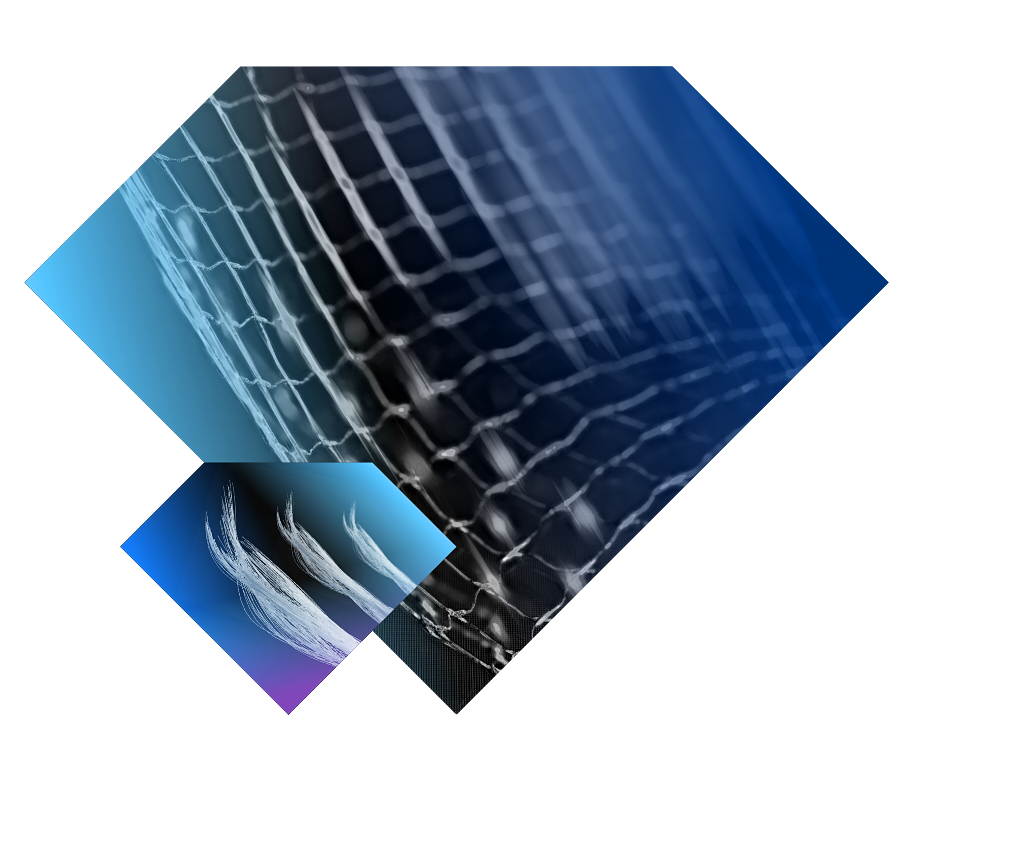

MADE FOR: Growout/containment nets

Smolt/small nets

Predator netting

Bird netting

Mooring systems

Dyneema® enables STRENGTHplus+

For more than 20 years, fish farming and harvesting systems made with Dyneema® have been proven to deliver strength plus much more – helping aquaculture enterprises to reel in success in a challenging industry.

Scaled-down weight for scaled-up efficiency

In aquaculture, every gram counts. Dyneema® fibers offer the same mesh breaking strength as conventional netting and roping materials but with significantly less weight (one-half to one-third of that of nylon).

This not only allows for the use of larger nets with less weight, but also minimizes the need for extra investments in equipment like boats, lifting cranes, and personnel. Simply put, Dyneema® gives you more with less.

As a uniquely lightweight option, Dyneema® also promotes durability. Lighter nets are easier and safer to work with, helping employees perform effectively for longer. And by putting less pressure on mooring systems, netting containing Dyneema® can extend the service life of other maritime equipment, too.

For high reliability at a low weight

Lightweight twine allows use of larger nets

Reduced investment in equipment and staff

Safer and more convenient handling

Less stress on mooring systems

Longer service lifetimes

Strength in more ways than one

There’s strong, and then there’s Dyneema® strong. Our fibers enable the construction of nets up to three times stronger than those made with traditional aquaculture materials of the same twine size.

Crucially, weight for weight, the amount of force on each net is reduced. That’s because Dyneema® directly minimizes drag by enabling thinner twine. Thinner nets also reduce the surface area that can be affected by fouling, which diminishes the need for costly anti-fouling coatings.

And there are more benefits to thin-twine netting made with Dyneema®. Such nets enable improved water flow, oxygen exchange, and shape stability, all of which leads to a healthier, less stressful environment for fish. The ultimate outcome? Better growth rates and lowered mortality in your fish harvest.

For unrivalled strength

Thinner twine, reduced drag force

Less exposure to fouling

Improved water flow and oxygen exchange

Better shape stability

Improved fish growth, reduced mortality

Delivering durability

In a competitive and cost-sensitive market, fish farmers are always looking for reliability and lasting value. At Dyneema®, we’ve got their back.

From rough seas to unwelcome predators, nets (and farmers) have to face some challenging opponents – and our high-strength fibers help them withstand every kind of threat, extending service lifetimes and reducing maintenance costs. Dyneema®’s advantages stand out in difficult situations, such as when diving costs are high, farms are in exposed locations, or predators are common.

Our fibers reduce weight and twine surface areas, minimizing anti-fouling costs, while their strength and easy handling mean less time needs to be spent on servicing and repairs. It all adds up to greater durability – which is why nets and ropes made with Dyneema® typically have longer service lifetimes compared to alternatives made with conventional materials like nylon.

For long-lasting nets

Superior service lifetimes

Exceptional water and bite resistance

Reduced anti-fouling with smaller twine surface

Less need for servicing and repairs

High-performance netting with sustainability entwined

When it comes to sustainability, less is more. Thanks to their reduced surface area, nets made with Dyneema® require less anti-fouling coating. Not only does this help create a healthier environment for fish, but it also reduces metal solids depletion by up to 50%.

Less weight also means a lower impact. Nets made with conventional Dyneema® produce 65% fewer CO2 emissions from netting compared to nylon cages, while our new bio-based Dyneema® fiber has a 90% lower carbon footprint than generic HMPE.

Plus, our commitment to sustainability is reflected in our efforts to create a fully circular value chain for Dyneema®. That’s why we’ve already introduced a Dyneema® alternative that repurposes mixed plastic waste as feedstock. And why we’re working to achieve a fully recyclable Dyneema® fiber by 2025.

For a more sustainable operation

50% less metal solids depletion

65% reduction in CO2 emissions

Up to 90% CO2 reduction with bio-based Dyneema® fiber

Mixed-plastic-waste alternative available

Fully recyclable Dyneema® by 2025

Want the same high performance with a lower carbon footprint?

Discover bio-based Dyneema® fiber

Stronger together

We work with leading aquaculture net and rope manufacturers around the world. Like us, they understand the value of trustworthy, high-performance equipment: equipment that goes beyond the industry standard to deliver long-lasting performance in all conditions. From the Mediterranean to the North Pole, Dyneema®-based nets and ropes are developed with the needs and challenges of local customers in mind. And, of course, we always comply with local regulatory standards.

Where to buy

Aquaculture nets and ropes made with Dyneema® are available from our trusted sellers around the globe.

Find a providerRead our case studies

Explore more

Commercial fishing ropes and netting

Discover how Dyneema® nets operational performance, crew safety, sustainability, and profitability in commercial fishing.

Mooring lines

Synthetic mooring lines set the standard for safety – but Dyneema® is raising the bar. Meet the safest choice in any port.

Fish farming

Dyneema® has reeled in decades of superior reliability, sustainability, and safety across all aquaculture environments.